At the end of August, we visited the Auto Research Center in Indianapolis, IN to perform some product testing in their wind tunnel. We've recapped our testing in several blog posts, breaking it down by product to provide a more concentrated review. Before we arrived to ARC Indy, we constructed a "lawn stage" to bolt down into the wind tunnel testing platform. When we arrived at the research center, there were two technicians who assisted in our set up and operated the wind tunnel. They provided us with red yard to help illustrate wind speeds.

We performed the Corostake testing very similar to the other product tests. We started out by testing the Corostake alone. We started the wind tunnel at 5MPH and incrementally increased wind speeds by 5MPH.

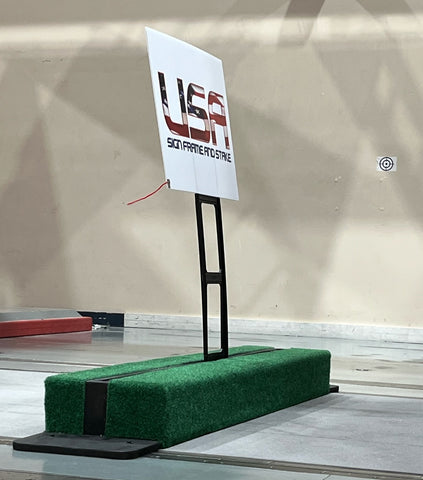

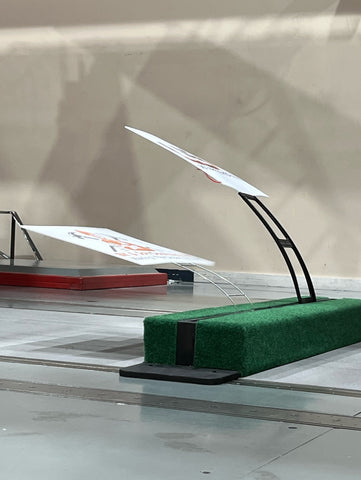

(above): The Corostake in the wind tunnel testing platform at 0MPH

(above): The Corostake in the wind tunnel at 5MPH

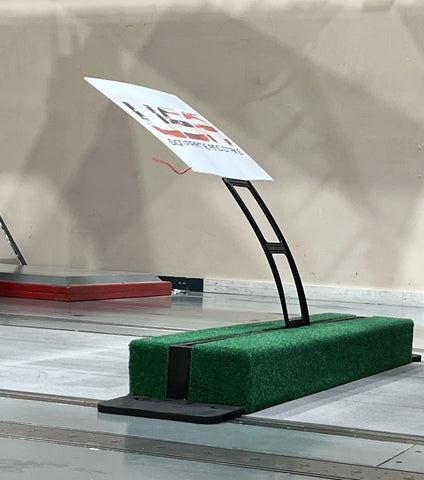

(above): The Corostake in the wind tunnel at 15MPH

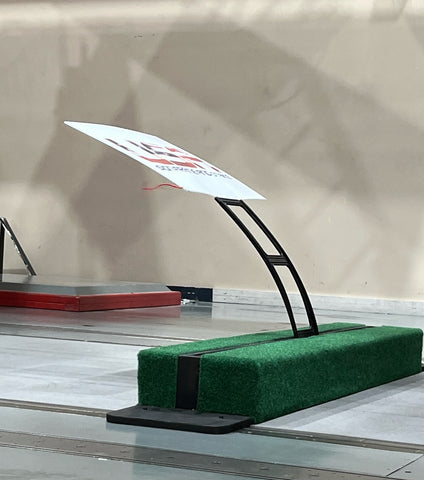

(above): The Corostake in the wind tunnel at 20MPH

(above): The Corostake in the wind tunnel at 30MPH

(above): The Corostake in the wind tunnel at 35MPH

(above): The Corostake in the wind tunnel at 40MPH

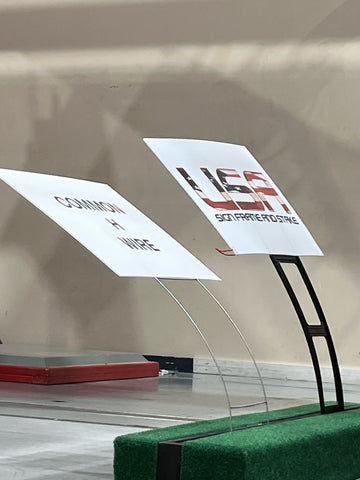

(above): common H wire stake (L) and Corostake (R) in wind tunnel at 0MPH before testing,

(above): common h wire stake (L) and Corostake (R) in wind tunnel at 10MPH

(above): common h wire stake (L) and Corostake (R) in wind tunnel at 20MPH

(above): common h wire (L) and Corostake (R) in wind tunnel at 30MPH

(above): common h wire (L) and Corostake (R) in the wind tunnel at 35MPH

(above): common h wire stake (L) and Corostake (R) in the wind tunnel at 40MPH

The Corostake showed much greater wind resistance than the typical H wire sign frame we tested it against. When we stopped the wind tunnel, the Corostake once again returned to an upright, straight position and no damage was observed on the stake. The H-wire was bent after our testing. In the photo below, the wind tunnel was turned off. (The red yarn illustrates a bit of motion due to the residual wind moving through the platform. No forced air was blowing at this time).

We brought a few commonly used wire yard sign frames with to test alongside the Corostake. After completing the first round of side by side testing, we switched the h wire stake out for a new one and repeated the next round of tests in the same manner. Again, we used the same size signs on both stakes.

(Foreground R) Bent Common H wire stake (background L) inserting a new h wire stake in the lawn stage

(L): Typical H Wire stake (R): Corostake in wind tunnel at 0MPH

(L): Typical H wire stake (R): Corostake in wind tunnel at 10MPH

(L): Typical H wire stake (R): Corostake in wind tunnel at 15MPH

(L): Typical H wire stake (R): Corostake in wind tunnel at 20MPH

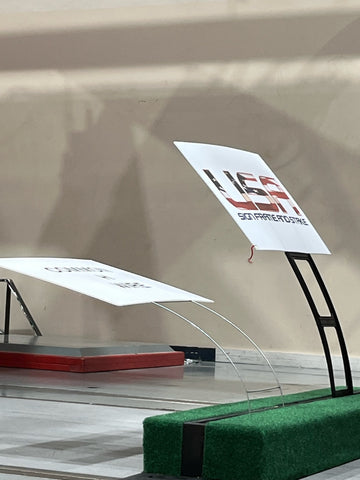

(L): Typical H wire stake (R): Corostake in wind tunnel at 25MPH

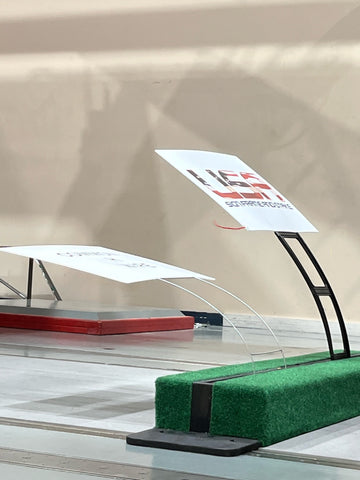

(L): Typical h wire stake (R): Corostake in wind tunnel at 30MPH

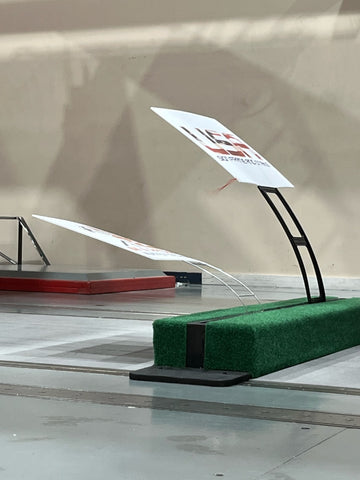

(L): Typical h wire stake (R): Corostake in wind tunnel at 35MPH

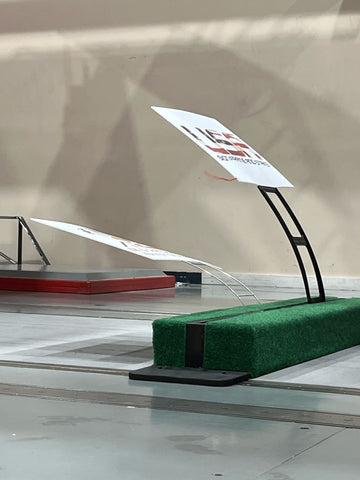

(L): typical h wire stake (R): Corostake in wind tunnel at 40MPH

(L): typical h wire stake (R) Corostake in wind tunnel after testing ended.

The Corostake performed better than the competitor stake in this round of testing as well. Once we stopped the wind tunnel, the Corostake returned to its straight, upright position. No damage or bend was observed in the wires on either end of the Corostake. The typical h wire stake used in this round of testing was bent at the end and did not return to a straight position.

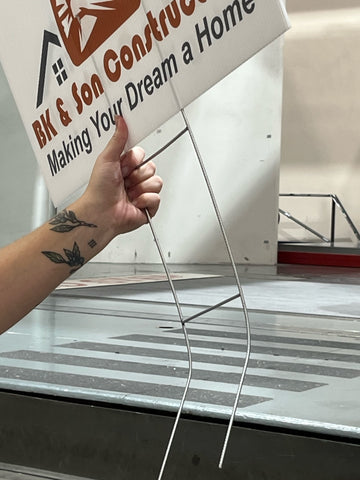

Our 30" tall Corostake is constructed with fiberglass reinforced polypropylene, with dual wire ground entry points and signage posts constructed of cold drawn hard wire steel. These wires are much harder and more rigid than the wire used to make most h wire stakes, meaning they won't bend, rust, or corrode.